Quality Control

Ohishi Sangyo engages in strict quality control in each of its business divisions. And each of our divisions has secured ISO certification.

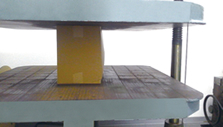

Metallic Mould for Pulp Mould Production

Each of our production hubs pursues strict quality control utilizing their own unique design and testing systems. Mold designs are tailored for each order followed by shock-absorbency testing and other measures.

-

Testing Laboratory

In order to improve the quality of our pulp mould products, we have established a testing laboratory where we perform a variety of tests, such as strength and drop testing.

-

Mould Cleaning Room

The metallic mould is the heart and soul of the pulp mould product. Each production plant is equipped with a mould cleaning room where the metallic moulds are scrupulously cleaned and maintained.

-

Foreign Matter Imaging Detector

This device detects foreign matter adhering to raw materials. It is used on pulp mould production lines and relies on image detection to spot foreign matter.

Plastic Film

We have developed operating procedures which our employees scrupulously follow regarding the management, correction and maintenance of inspection, measurement and testing equipment so that we can ensure consistency in product supply and quality to customers.

The following are some key examples of how this is put into practice.

-

Defect Detector

This device uses a camera to detect defects in plastic film, recording and mapping any which are found. It is used on all plastic film and T-die embossed film production lines.

-

Non-contact-type Thickness Gauge

This device automatically measures, records and graphs film thickness. It is used on the production line for T-die embossed film.

-

Autograph

This equipment is used to measure film tensile strength, elongation, peel strength and coefficient of dynamic friction.

Heavy Duty Bag

Our top priority is providing customers with safe and reliable products - a goal towards which we apply our many years of accumulated experience, data and know-how. Furthermore, we employ a food management safety system(*) to ensure consistently stable quality.

For us, customer satisfaction is inextricably linked with product quality. Thus, our highly experienced technical staff as well as production and sales staff work as one to fastidiously satisfy a diverse array of customer requests.

*ISO22000:2005 and MS1480:2007 certification acquired by the Core Pax (Malaysia) Sdn.Bhd. plant in October 2014

-

Quality Control Room

This room is capable of testing a variety of aspects, including tensile strength, tearing strength, stretch, air permeability, abrasive resistance and slip resistance.

-

Tensile Strength Testing

The amount of energy involved in fracturing (breaking) samples which conform to given specifications is measured and used as the tensile strength value.

-

Drop Testing

It is the test that person has assumed a state in which to lower the luggage . In addition to the horizontal drop test , there is also a method for testing vertical fall or side fall .

Corrugated Board

Ohishi Sangyo has been manufacturing cardboard containers since 1953, giving us a track record and experience stretching back a great many years.. From this we have built up a database which we can use as a stand-alone resource enabling us to perform quality control checks for any number of scenarios and situations.

-

Printing Detector

A printing detector is installed at our cardboard production plant in Kitakyushu. This device helps enhance the quality of the cardboard we produce by visually inspecting every piece to prevent misprints and poor print quality.

-

Sample Cutter

With this device we are able to quickly create samples according to customer requests.

-

Compressive Strength Tester

This device is able to measure cardboard strength. By regularly testing this, we ensure uniform quality.